Contoh Laporan Program Supervisi Kepala Sekolah Update 2018 ini sengaja kami bagikan supaya dapat membantu anda sebagai Kepa Sekolah SMA/MA/SMK/MAK dalam mempersiapkan perangkat Program Supervisi serta administrasi Kepala Sekolah yang harus anda miliki dan melengkapi tugas anda. File Contoh Program Kerja Supervisi Akademik Kepala Sekolah Download Format File Microsoft Word pada shared link di atas disimpan di Google Drive untuk memastikan file-file aman dari virus atau malware. Karena ketika file diupload ke Google Drive, file secara otomatis diperiksa dan di-scan antivirus oleh sistem Google Drive Cloud Storage. Bagi yang membutuhkan Program Supervisi Akademik, disini saya sediakan lengkap Program Supervisi Kepala Sekolah SD, SMP, SMA, SMK yang sudah dilengkapi dengan Instrumen Supervisi yang bisa anda download secara gratis. Laporan program supervisi kepala sekolah sma.

Mastercam 2017 is the new replacement for Mastercam X9, that delivers CAD/CAM tools for all types of programming, from the most basic to the most complex.Whatever your machining needs, Mastercam is the most perfect CAM software ever, be it 3D design and drafting, multiaxis machining, multiaxis milling and turning, free-form modeling and cutting, router applications, surface and solid modeling.

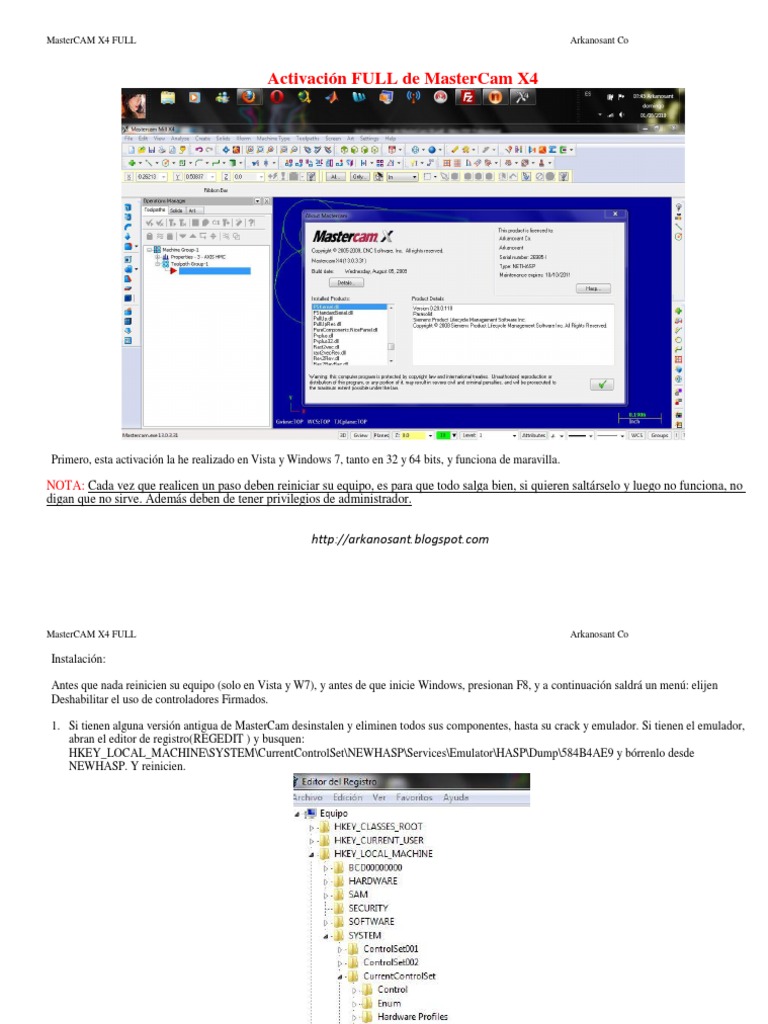

Download Mastercam X4 32bit 64bit full crack 100% working forever Link Mastercam X4 x86 x64 full license forever Mastercam X4 win32 win64 crack high speed downloading Mastercam X4 32bit 64bit full crack Machining with Mastercam X4 32bit 64bit full crack Mastercam is one of the easiest in the study and operation of CAD / CAM systems, while it has extensive modeling capabilities and a solid set of processing strategies. According to the independent consulting expert CIMdata – Mastercam, the most widespread CAD / CAM system in the world. Effective automated 2D processing To perform 2D processing, Mastercam for SolidWorks has a powerful feature of Automatic Design Processing based on the recognition of elements of geometry (FBM).

Analyzing the detail for the presence of specific elements of geometry (surface, size, arrangement of holes, etc.), the FBM function automatically creates an effective strategy for processing the recognized elements. Among the main functions are the following: * Trimming in case of detection of allowance above the surface of the part. * Processing of open, embedded and through pockets. * Trajectories of roughing and finishing for each pocket. * Recognition of holes and creation of operations for centering, drilling, unfolding, chamfering, and tapping according to specified criteria. Roughing and finishing 3D processing, including post-processing The basic sample effectively removes the bulk of the allowance. High-speed machining (VCO) provides the technology of the fastest machining and obtaining of excellent surface quality of products.

The CommView For Wi-Fi 7.3 Crack supports more than 70 protocols and also able to see the minutest detail of the captured packet and then display in the form of a tree like structure that is used to display the crack protocol layers’ details and packet header details. The utility gathers data from the wireless adaptor and then analyzes the packets by decoding them. Commview For Wifi Crack Download Latest Version 2017 CommView for Wi-Fi is a special version of CommView software and is designed to capture and analyze data packets on wireless network 802.11 a/b/g networks. With the help of CommView for WiFi 7.0 Full Download + Crack you can pinpoint the network crack problems and also trouble shoot issues related to hardware and software. Commview for wifi reassociaciya uzlov ne rabotaet free. The detailed and clear picture of crack data packets produced by CommView for Wi-Fi helps in getting the detailed information of network traffic.

Mastercam includes a set of fully associative high-speed processing paths that allow you to maximize the capabilities of your CNC equipment. * Strategies “Basic Sampling” and “Cleaning Area” effectively remove the main volume of allowance by using trajectories that are adjustable to “scrape” the workpiece or “gnaw out” the material from the cavities.

* The “Pre-working” strategy smoothly removes the allowance left after the previous roughing passes. * Using a constant 3D step between the passes, a clean “comb-like” strategy forms the same surface quality (roughness) on the inclined and flat surfaces of the part. * The horizontal strategy “Horizontal areas” quickly processes the flat horizontal surfaces of the part. * “Spiral”, “Radial” and “Raster” processing strategies provide extensive opportunities for processing parts of different types. Video * “Pencil” strategy creates tool movements along the lines of intersection of the solid body faces for the purpose of processing hard-to-reach parts of the part. Reliable testing of trajectories Verification of the treatment of a solid body with imitation of material removal makes it possible to check the trajectories before they are actually worked out on the machine.

Mastercam gives you confidence that you can perform any level of complexity processing on your hardware. Using the tools available in Mastercam to check the trajectories, you can easily make sure that the trajectories and movements are created exactly the way you wanted it. * You can view and measure a part in the process of verifying the machining of a solid part from a solid billet. During simulation, the tool and the cartridge are displayed and checked for cut-in. * It is possible to draw trajectories using the “Backplot” tool and get the processing cycle time. You can dynamically view all the necessary information about the tool and the operation at any point of the path, as well as scale individual areas for a more detailed view.

* Fast verification of 2D trajectories with tool drawing to check the final result of finishing operations. Effective tools for creating control programs and managing trajectories The trajectory of the movement of the instrument is just part of what, as a result, forms a good control program. Universal control of the trajectories, as well as the settings of the machine and the CNC system, optimize each operation as much as possible. * Full control of all aspects of the approach and retraction of the tool. * Safety zones help to ensure the safety of tool retraction movements when working with any type of trajectory. * Significant reduction in program size due to the use of the path filter. * Use of all types of tools: ball, disk, conical, etc.